Live monitoring and emissions feeds

We are committed to continually improving the environmental performance of the Munster Plant and reducing any potential impacts on the community and environment.

Between 2005 – 2012 more than $74 million was invested in capital improvements on the Munster Plant to reduce our environmental impact.

Only two kilns are operating at Munster for the production of lime – Kilns 5 and 6- since the production of clinker stopped in 2015.

The stack emissions from both kilns are regulated by the Department of Environment Regulation via Cockburn Cement’s licence under the Environmental Protection Act 1986.

Through a system of BAM (Beta ray attenuation method) monitors in key locations across the Munster site, live monitoring of particulate concentrations are published on an hourly average. The BAM equipment has been designated by the United States EPA as the Federal Equivalent Method for monitoring PM 10.

Particulate monitoring system

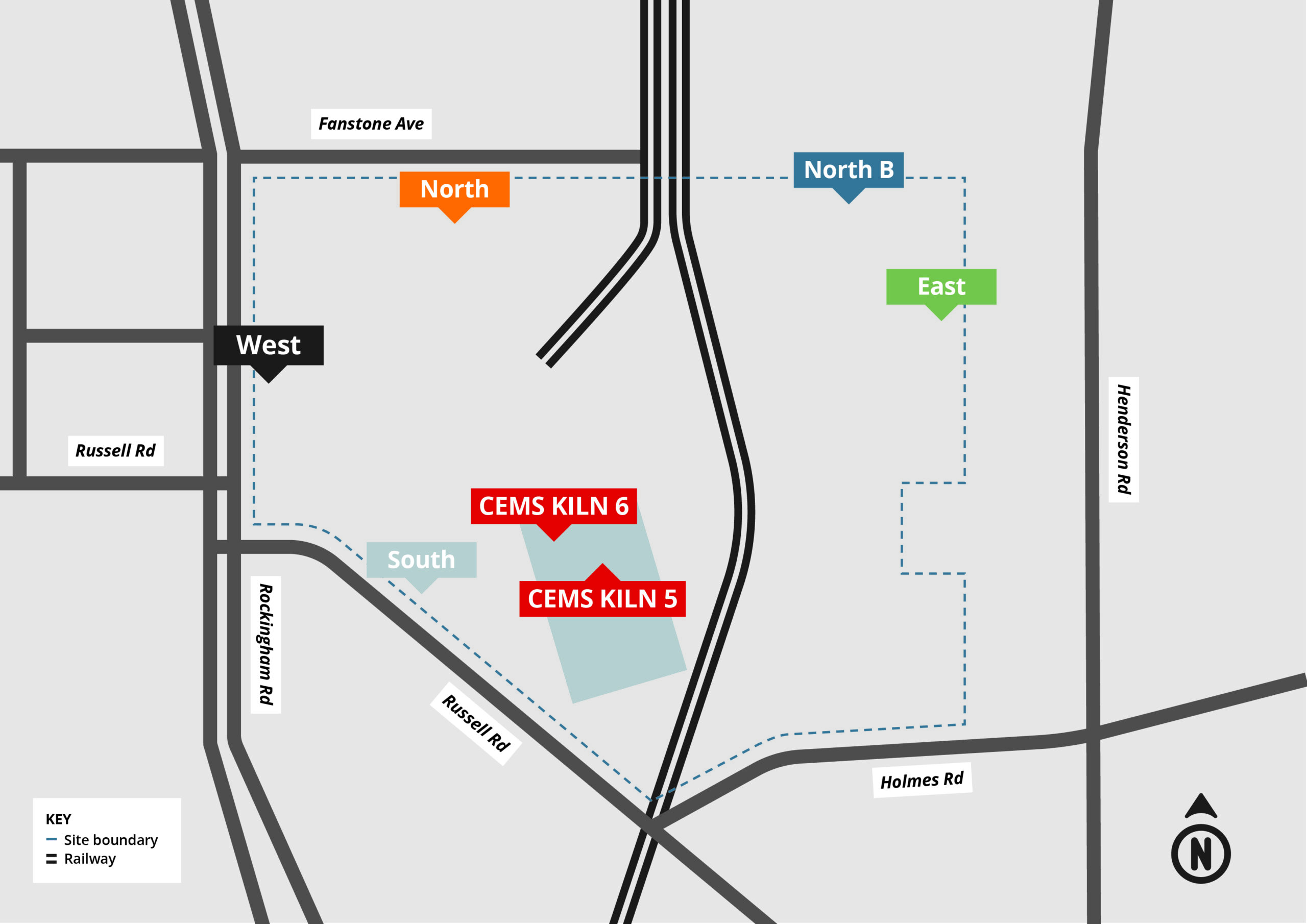

The map below identifies the locations of each of the BAM’s monitors within the Munster site boundary. The colours used on the map relate to the table above.

What are Particulates?

Particulate matter, or PM, is a term describing particles suspended in the atmosphere. Particles may be solid or liquid. Particulate matter is a generic and regulatory term often used interchangeably with simpler terms such as smoke, soot, haze and dust.

The potential effect of particulate matter on the environment, human health and amenity depends on the size of the particles, the concentration of particulate matter in the atmosphere and rate of deposition.

Particulate matter is measured by concentration, the mass of particulate matter that is suspended per unit volume of air. It is usually reported in micrograms per cubic metre (µg/m3).

Particulate matter with an aerodynamic diameter greater than 10 micrometres (µm) tends to be associated with amenity impacts, while particulate matter less than 10 µm is associated with health impacts. For this reason, particulate matter is sub-divided into a number of metrics based on particle size.

PM10 refers to particles suspended in the air with an aerodynamic diameter less than 10 µm.

What is the source of Particulate matter?

Particulate matter can come from a variety of sources, including:

- Industry

- Residential/domestic

- Natural – such as salt spray, bush fires and wind erosion of bare earth

- Motor vehicles through combustion of fuel, and wheel and brake generated dust

All these sources are present in the Munster area.

What are the air quality standards for Particulate matter?

The Environment Protection Act 1986 (EP Act) provides for prevention, control and abatement of pollution and environmental harm, for the conservation, preservation, protection, enhancement and management of the environment and for matters incidental to or connected with the foregoing in Western Australia.

Cockburn Cement operates under EP Licence 4533/1967/15 which prescribes ambient air quality limits and response levels the company must comply with. If the 1-hourly average PM10 exceeds 90ug/m3 Cockburn Cement are required to investigate the source of the dust emissions by visual inspection of activities on site and must undertake corresponding management actions if the activities are found to be on Cockburn Cement’s site.

About our continuous emissions monitoring systems (CEMS)

We operate a Continuous Emissions Monitoring System (CEMS) as part of our operating licence. The CEMS provides, on a continuous basis throughout the day, a permanent record of emissions from kilns 5 and 6.

The CEMS monitors particulates (opacity), sulphur dioxide and nitrogen oxides. The data is logged to an environmental emissions database and is reported each month to the Department of Water and Environment Regulation (DWER).

Independent, NATA accredited stack monitoring and modelling

Our stack emissions are regulated by DWER via an Environmental Protection Act 1986 licence. As part of our licence an independent NATA accredited consultancy conducts quarterly stack monitoring on kiln 5 and 6 for specific pollutants. This data is then used to determine the ground level concentration of the pollutants.

Modelling of the ground level concentration is carried out using the Ausplume version 6.0 dispersion model. The model configuration has been developed by the independent NATA accredited consultancy. The ground level concentrations are compared with various state, national and international air quality standards and guidelines. The results of the stack monitoring and modelling are reported quarterly to the DWER.